- Welded aluminum base assembly, using 1-1/2" square, 1/8" wall tubing

- Anti-slip, vibration-dampening, support feet

- Aluminum t-slotted mounting rails, allowing for attachment of tethered motor assembly and mechanical connection to associated devices

- 16-Gauge, formed-steel support structure, allowing for attachment to base assembly or alternate mounting bench products

- 16-Gauge, formed-steel electrical enclosure

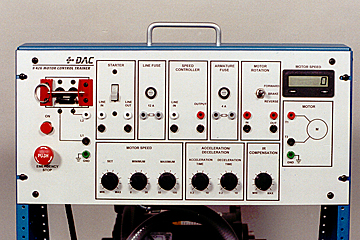

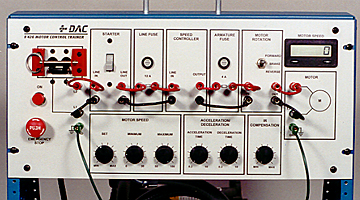

- Silk-screened 1/8" aluminum front panel face

- Powder-coated surfaces throughout

- On-board safety components, including: 1) Keyed instructor power switch (Rear of product); 2) Circuit breaker with provision for representative lock-out/tag-out; 3) Permanent, redundant internal grounding (not dependent on student wiring); 4) Pilot light and large emergency stop switch; 5) Internal electrical interlock, de-energizing power when opening electrical enclosure; 6) Use of premium shielded banana jack patch cords

- Industrial-duty, 56C-frame, 1/4HP, 1750RPM, 90 VDC permanent magnet motor

- Internal, on-board DC motor controller with panel-mounted connections, control components and system fuses

- On-board wiring devices including stop/start switch, forward-Brake-Reverse switch as well as controller function rheostats including speed, acceleration/deceleration and IR compensation

- On-board, magnetic speed sensor and panel-mounted digital tachometer display

- Color-coded, banana-jack receptacles for all motor leads, supply connections and control components

- Four instructor fault switches (rear of device, behind access panel)

- Allows for attachment to optional control and mechanical devices directly and using optional mounting bench products

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- 19-in. L x 19-in. W x 25-in. H (480 x 480 x 670 mm)

- 50 lbs. (22.5 kg)

115V/60Hz/1Ph power

Requires #410-001/E Portable Digital Multimeter, #410-002 Non-Contact Tachometer Kit, and #410-100 Prony Brake Assembly

Includes Keyed Instructor Power Switch, Circuit Breaker, Pilot Light, E-Stop Switch, Electrical Interlock, Magnet Motor, DC Motor Controller, Magnetic Speed Sensor and Panel-Mounted Digital Tachometer Display, (4) Instructor Fault Switches