Control Valve Training System Plus

Model: 618-CTL

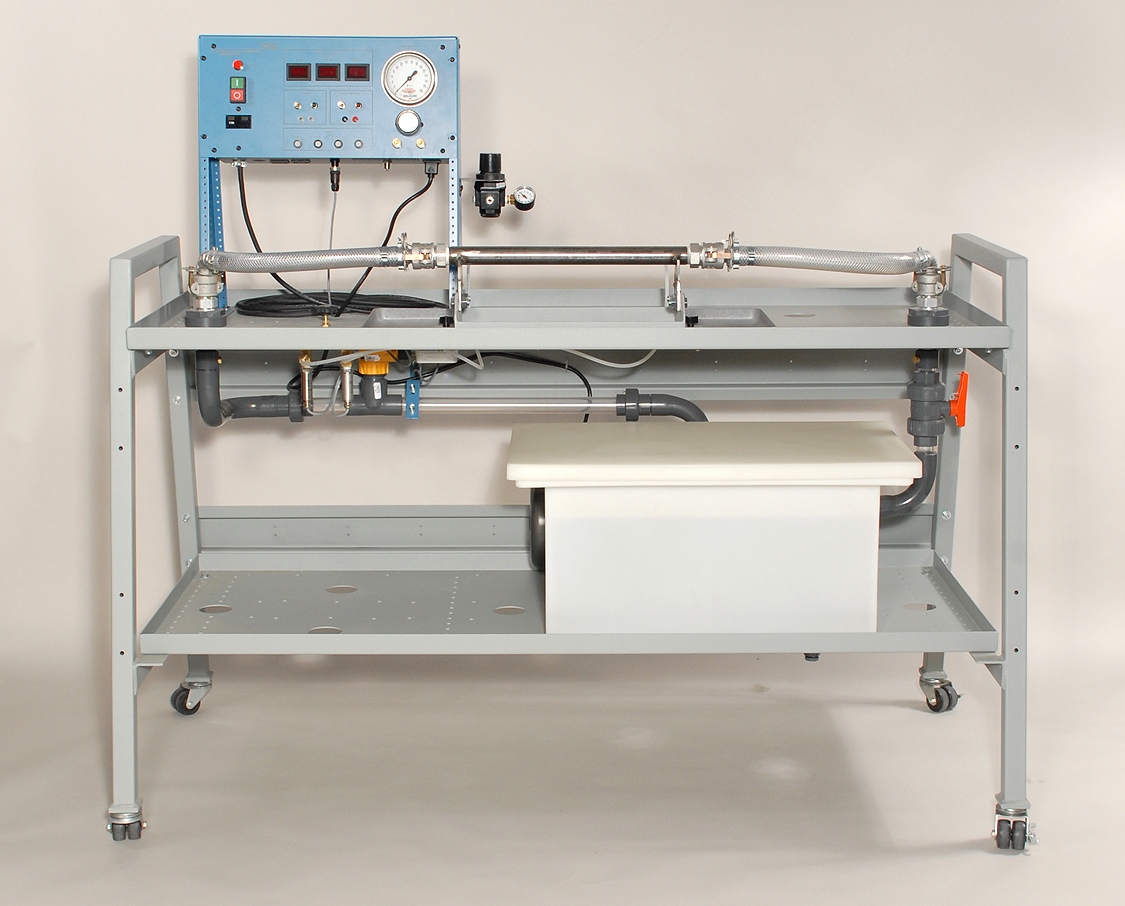

DAC Worldwide’s Control Valve Training System Plus (618-CTL) is a working, large-scale fluid process system that allows for hands-on training related to the design, calibration, and testing of common control valves used in industry. The device includes provisions for mounting control valves of different designs, including diaphragm-type valves, by a variety of manufacturers. The device, coupled with a comprehensive student manual, creates a complete, self-paced learning system that reflects realistic industrial and commercial applications.

This self-contained training system provides for complete, realistic courses in instrumentation control and calibration within a heavy-duty learning system. Useful within industrial training programs or in an educational setting, the Control Valve Training System Plus will help make this fundamental part of instrumentation maintenance training more memorable and effective.

The complete package includes a Control Valve Training System (618), a Control Valve Demonstration Set (618-001), and a PID Controller and I/P Converter Panel (600-066).

Practice Hands-On Process Control Skills for Various Applications

The basic instrumentation training system workstation includes a magnetic flow meter and two pressure sensors in order to demonstrate performance at different flow rates using multiple valve plug and trim designs. Field calibration of valves and positioners can be accomplished using a high-quality regulator and test gauge. With optional and/or user-supplied equipment the device can be used to create basic process loops incorporating flow control.

The workstation utilizes a 14-gauge welded steel frame, with four casters and two (2) support shelves. The power/meter module includes a 19-inch rack panel, enclosure, and a 16-gauge steel support structure. Additionally, the panel-mounted components are industrial quality and include two (2) digital pressure displays, digital flow display, pilot light, on/off switch, pump control with provision for external control via relays, GFI circuit protection, fuses, test gauge (0-30 psig), precision regulator, quick-connect air fittings, and electrical service outlets.

Hands-On Exercises and Learning Activities Lead to Realistic Results

DAC Worldwide’s Control Valve Training System Plus also features hands-on exercises and learning activities that focus more on results and less on secondary academic background information. This comprehensive training system offers content in instrumentation principles, with individual learning activities provided in a self-paced or instructor-led format. The integrated course features multiple activities, all of which include background information on the topic, hands-on experiments, and related review questions.

- Welded steel frame workstation using 14-gauge, 1-1/2" x 1-1/2" tube, and incorporating two 14-gauge support shelves

- Four (4) casters, two (2) with locks

- Clear, 1" diameter, PVC piping and fittings throughout.

- Primary reservoir, 15 gallon capacity.

- Power/meter module including 19" rack panel, enclosure, and 16-gauge steel support structure

- Panel-mounted components, including: two (2) digital pressure displays, digital flow display, pilot light, on/off switch, pump control with provision for external control via relays, GFI circuit protection, fuses, test gauge (0-30 psig), precision regulator, quick-connect air fittings, and electrical service outlets

- Enclosure-mounted supplemental, 4-20 mA, flow meter connections

- Service air regulator and quick disconnects

- Industrial hose connectors and hose allowing for attachment of demonstration valves

- Quick-disconnect tubing fittings allowing for attachment of instruments

- Magnetic flow meter, monitoring upstream flow

- Throttling ball valve on downstream flow

- Centrifugal pump, 1 HP, with inlet strainer

- Provision for mounting optional rack-mounted instruments

- High-durability, powder-coated surfaces throughout

- Crating for shipment via motor freight

Includes:

- 618-000 - Control Valve Characteristics Training System

- 618-001 - Control Valve Demonstration Set

- 600-066 - PID Controller and I/P Converter Panel

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

63in x 24in x 50in (1600 x 600 x 1275 mm)

255 lbs. (116 kg) - Shipping Dimensions

(L x W x H)

67in x 37in x 64in (1701 x 939 x 1625 mm)

523 lbs (237 kg)

- #600-006A - Test and Calibration Package, Hand-Held, Economy

- #910 - Rolling Rack Assembly

- #600-051 - Strip chart recorder, 2-pen (Yokogawa, SR 1000) (additional)

- #618-500 - Additional Use/Exercise Guide

- #940-001 - Control Module Base Assembly

- #940F - Control Module Assembly Frame (for supplemental panels)

- 100', 1/4in. Diameter instrument connection tubing

- Six (6) Quick-disconnect nipples

- Six (6) Tubing tees

- Six (6) Tubing couplers

- Use/Exercise Guide

- 220V/50-60Hz/1Ph power

- Water Source