Process control systems maintain precise control of liquid and gas variables, such as liquid level, flow rate, pressure, temperature, and pH level. These multifaceted systems are a critical part of major industries like power generation, refineries, petrochemicals, chemical manufacturing, pharmaceuticals, biotechnology, and food processing and bottling.

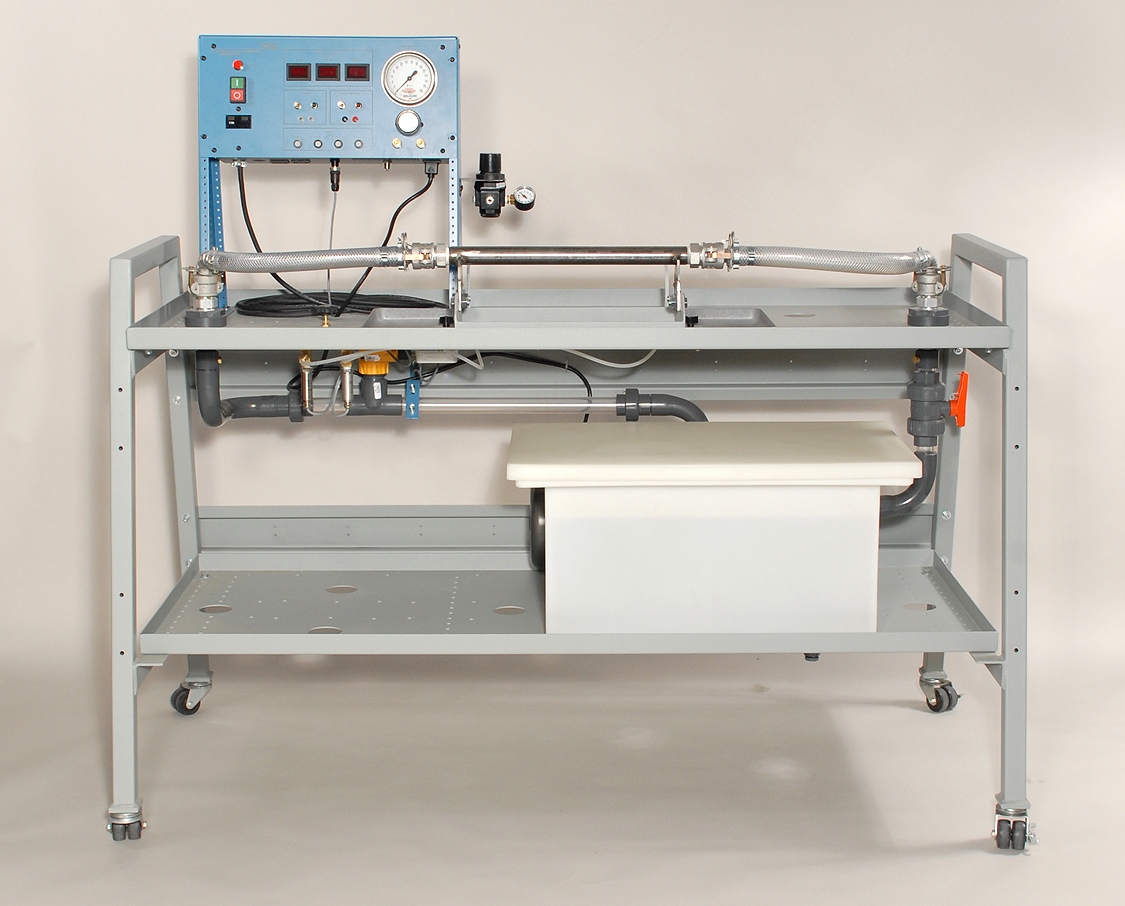

DAC Worldwide’s Control Valve Characteristics Training System (618-000) is a working fluid process system, allowing for hands-on training relating to the design, calibration, and testing of common control valves used in industry. The system includes provision for mounting control valves of different designs, including diaphragm-type valves, by a variety of manufacturers.

Study Control Valve Characteristics with Hands-On Training System

A magnetic flow meter and two pressure sensors are provided in order to demonstrate performance at different flow rates using multiple valve plug and trim designs. Field calibration of valves and positioners can be accomplished using a high-quality regulator and test gauge.

With optional and/or user-supplied equipment the Control Valve Characteristics Training System can be used to create basic process loops incorporating flow control.

The system requires the #600-006A Economy Standard Test and Calibration Equipment Package and #600-066 PID Controller and I/P Converter Panel. The system also requires valves in order to operate. These valves can be purchased from DAC Worldwide or donated from industry. It includes a workstation, caster set, two digital pressure displays, digital flow display, pilot light, GFI circuit protection, test gauge, precision regulator, service air regulator, magnetic flow meter, and centrifugal pump.