Compound wound DC motors are a hybrid between series wound and shunt wound motor designs. Also called cumulative compound motors, they feature the combined characteristics of series wound and shunt wound motors: high starting torque and efficient speed regulation.

These features make compound wound DC motors popular in a wide variety of industrial applications, such as: drivers, conveyors, freight elevators, electric shovels, ball mills, stamping machines, rolling mills, mixers, reciprocating pumps, hoists, metal shears, and compressors.

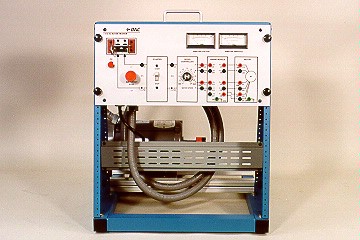

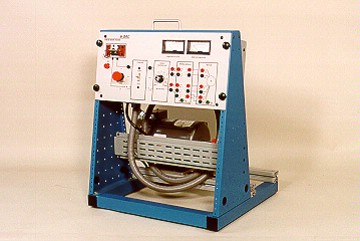

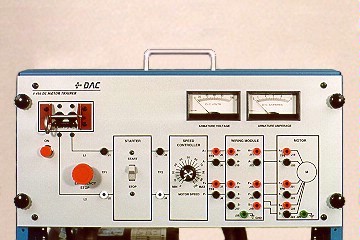

DAC Worldwide’s Compound, Cumulatively Wound, DC Motor Training System (416-000) features a common compound wound DC motor used frequently throughout industry. Each motor module includes a welded aluminum mounting baseplate, aluminum control box support structure, and a steel control enclosure.

The system requires the following items:

- #410-001E Portable Digital Multimeter

- #410-002 Non-Contact Tachometer Kit

- #410-100 Prony Brake Assembly

All motor wiring is accomplished through banana jack receptacles on the control enclosure’s front panel face. Each unit comes equipped with an appropriate voltmeter and ammeter. In addition, four instructor fault insertion switches are provided on each motor module.

Industry-Standard Components Provide Realistic, Hands-On Training

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Compound, Cumulatively Wound, DC Motor Training System features a wide variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The Compound, Cumulatively Wound, DC Motor Training System is a sturdy unit that features industrial-quality components, such as: compound wound DC motor mounted on T-slotted rails; master circuit breaker with lock-out/tag-out capability; color-coded banana jack patch cord receptacles; voltmeter; ammeter; enclosure cover safety interlock switch; fault insertion switches; large emergency stop switch; large pilot light; and keyed instructor power switch.

Courseware & Hands-On Exercises

The Compound, Cumulatively Wound, DC Motor Training System’s courseware consists of a textbook on motors and motor control, instructor and student wiring diagrams, and a Use/Exercise Guide with hands-on exercises. These can be used as part of either an instructor-led course or self-directed study.

Learners will explore a wide variety of fundamental motor control topics, including: motor control terminology and construction; motor nameplate data; and DC motor troubleshooting. Hands-on exercises include industry-relevant motor control skills, such as wiring and troubleshooting the compound, cumulatively-wound DC motor.

Expand Training Capabilities with Custom Options

The Compound, Cumulatively Wound, DC Motor Training System can be customized with a variety of options to create a training system that matches a particular industry’s or user’s specific needs. In industry, one size rarely fits all and this trainer can be tailor-made to your exact needs.

For example, training capabilities can be expanded by adding the following available options: motor loading module; instructional videos, handbooks, and training manuals; portable digital multimeter; non-contact tachometer; and prony brake assembly.