Centrifugal compressors, also known as radial compressors, generally run at speeds of 20,000-30,000 RPM. They’re usually engine or turbine driven, given their high rotating speeds.

Centrifugal compressors are perfect for applications requiring high volume and low compression ratios, such as oil and gas production/transmission applications. They’re also commonly used in refineries, as well as in pipeline booster service and very high flow rate gas lift service.

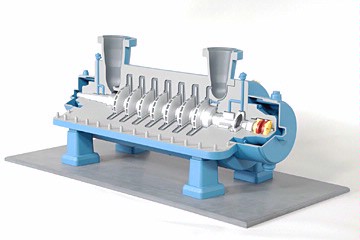

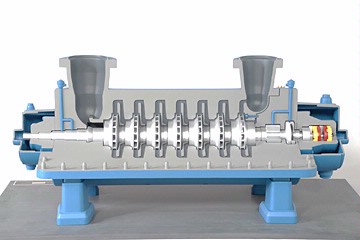

DAC Worldwide’s Centrifugal Compressor Model (211C) is an incredibly-detailed scale model that depicts features of both barrel-type and horizontally-split, multi-stage centrifugal air compressors.

Industry-Standard Components Provide Realistic, Hands-On Training

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Centrifugal Compressor Model depicts a wide variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The design of the Centrifugal Compressor Model is based upon common industrial centrifugal compressors manufactured by companies like General Electric, Hitachi, Elliott, Rolls Royce, Solar, and Dresser-Rand. Its convenient size, attention to detail, multiple cutaways, and instructive color-coding all combine to make it a useful training tool for those learning about compressor operation/maintenance and process plant equipment.

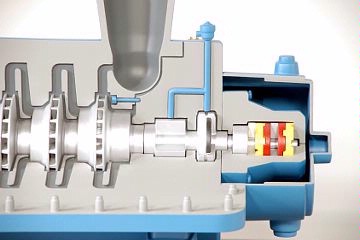

For example, the model includes all primary features of a centrifugal compressor and also depicts the internal flow path. The primary housing and secondary components are sectioned to allow learners to view internal components and visualize assembly and disassembly procedures.

External details featured in the model include: inlet and discharge nozzles, casings, support piers, closure rings, oil connections, and bearing housings. Featured internal details include: diaphragm assembly, stylized thrust bearing assembly, rotors, impellers, stylized shaft seals, journal bearings, shear rings, and flow path.

The Centrifugal Compressor Model is mounted on a durable PVC base. It can be customized with options, such as a reference guide to rotating equipment or a mobile display stand.