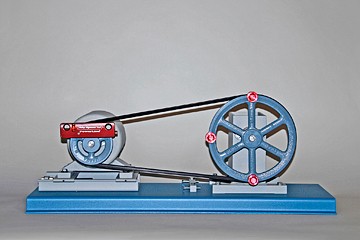

DAC Worldwide's Sheave/Sprocket Laser Alignment Tool (201-005) is a magnetic, laser-type sheave and sprocket alignment system that facilitates alignment of belts, pulleys, sheaves, gear trains, rollers, platforms, conveyors, and other industrial devices. The product replaces inaccurate and time-consuming methods using straightedges and string alignment, which are currently in use. Compared to these older methods, the device is easier, faster, and more accurate. Ultimately, you will greatly reduce downtime and belt failure through its use.

Enhance Industrial Learning with Belt Drive Last Alignment Training

To use the belt drive last alignment tool, simply mount the magnetic laser source on the movable sheave. Install the three magnetic targets on the driven sheave or sprocket at the 12, 9, and 6 o’clock positions. A visible horizontal laser beam will be visible on all three targets. Align equipment until the projected laser line strikes the center of the groove on all three targets simultaneously. This system simply corrects both parallel and angular misalignment. Proper alignment minimizes premature belt wear, and improves mechanical efficiency. This system is not computerized and no programming is required. A single craftsman can perform precision belt alignment unaided.

Made of high grade anodized aluminum, this device is weather-resistant, rugged, and durable. The beam’s optical window is coated with a high performance protective film. Magnets are nickel-coated to prevent rusting.

This product is carefully factory calibrated so that the laser line is emitted exactly 0.312in. above the bottom magnet surface for accurate performance. An on-board level vial is also factory calibrated. No field calibration is required.