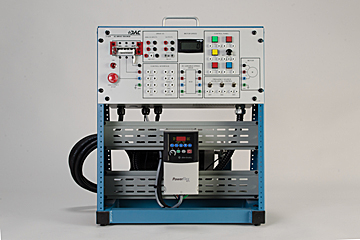

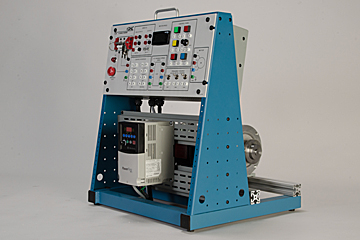

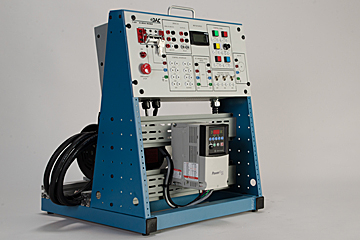

- Welded tubular aluminum baseplate with t-slotted mounting rails for mounting a 56-frame motor (allows for attachment to the DAC 419 Motor Loading Device)

- Powder-coated 16-gauge steel electrical wiring enclosure and support frame assembly, which can be mounted directly on the DAC 905 Electromechanical Bench

- Industrial 3-phase inverter-duty, 1/2 hp. motor

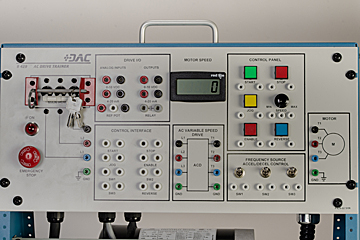

- 3-Pole circuit breaker with provision for lock-out/tag-out

- Pilot light and emergency stop switch

- Safety interlock, de-energizing internal wiring upon removal of front panel face

- Silk-screened panel face identifying all components, wiring points and test point locations

- Keyed instructor switch (rear of device)

- Simulated remote operator control panel with pre-wired switches

- Twenty-nine (29) banana jack connections for all drive I/O points and control interface connections

- Thirty-five (35) tip-jack (test) connections for troubleshooting motor, drive and control wiring

- Digital tachometer with magnetic pick-up

- Permanent internal ground wiring

- Eight (8) instructor fault switches (rear of device)

- Allows for connection to DAC 464, 428 trainers and within automation arrangements on the 905/210 Electromechanical Bench

- Allen-Bradley PowerFlex 40 variable frequency drive with integral keypad and features as follows:

• Remote potentiometer input; Adjustable frequency

• 115 or 220 VAC input; Single or three phase, 50/60Hz

• Output: 2.3 A; 0.37 kW (0.5HP); Voltage adjustable from 0V to input voltage, 0-400Hz

• Analog Input: 0-10V, 4-20mA

• Inputs/Outputs: 3 Inputs; voltage, resistance, and amperage. 3 Outputs; voltage, relay, and amperage

• PLC Data (8 inputs)

• Optional DC dynamic braking

• Current limiting protection

• Programmable acceleration/deceleration, and on-board PID control loop

• Integral communication RS485

• Multiple Languages: English, Spanish, German - Crating for shipment via motor freight

- 3-Phase Inverter-Duty Motor

- 3-Pole Circuit Breaker

- Pilot Light and E-Stop Switch

- Safety Interlock

- Keyed Instructor Switch

- Simulated Remote Operator Control Panel

- 29 Banana Jack Connections

- 35 Tip-Jack Connections

- 8 Instructor Fault Switches

- PowerFlex 40 VFD

- #429-500 - Use/Exercise Guide

The standard courseware includes 26 exercises as follows:

- Introduction to the DAC #429E Variable Frequency Drive Trainer, Extended - PowerFlex40

- Variable Frequency AC Drive Theory, Terms and Abbreviations

- Investigating the Electrical Connections of the Allen-Bradley PowerFlex 40 Variable Speed Drive

- Checking the Nameplate Data

- Preforming Pre-Power Checks and Start Up

- Familiarization with the Front Panel Control and Indications

- Resetting the AC Drive Parameters to the Factory Defaults

- Checking and Setting Minimum and Maximum Frequency

- Checking and Setting Acceleration and Deceleration Timing

- Programming Over Current Safety Features

- Familiarization With Nameplate Parameters

- Checking and Setting Jog Parameters

- Observing and Plotting the Ramping Characteristics

- Programming and observing the Skip Frequency and Skip Frequency Bandwidth Controller Functions

- Programming Operating Frequencies (Motor Speeds)

- Programming AC Drive Outputs

- Using External Voltage and Current Sources of Motor Control

- Introduction to Troubleshooting

- Troubleshooting Exercises (8 Exercises Provided)

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- Product Dimensions

(L x W x H)

19in. x 20in. x 24in. (480 x 6508 x 10 mm)

68lbs. (31kg) - Shipping Dimensions

(L x W x H)

21in. x 24in. x 30in. (533 x 609 x 762mm)

105 lbs. (48 kg)

- 208-230V/60Hz/3Ph