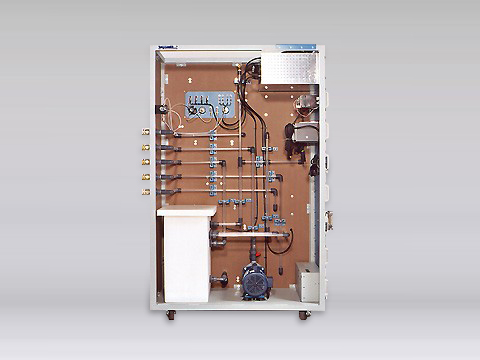

- One-piece, welded, 1/8" wall, tubular steel frame

- Four, 4" diameter casters, two with locks

- Integral, 19" x 70" high, instrument mounting rack, with silk-screened instrument and controller panels

- Rack-mounted, locking storage box for accessories

- Front panel faces fabricated from marine-grade 1/2" plywood and covered with a .040" thick, high-durability, surface treatment

- Clear, ½" diameter, PVC piping components throughout

- Clear acrylic tank, 3 gallon capacity

- Primary reservoir, 20 gallon capacity

- Centrifugal pump, ½ HP

- Circuit breaker with GFI circuit protection

- Two solenoid valves, allowing for the creation of flow supply and demand disturbances both at the tank outlet and in a bypass surrounding the control valve

- Power distribution panel, mounted in instrument rack including on/off power switch, GFI receptacle, fuses for all circuits, and 12 electric “free line” connections to the front panel

- Front panel-mounted, operator control panel, including switches and pilot lights for: a pump, and two solenoid valves, as well as control relay connections for equipment, 24 VDC power supply terminals and electric “free line” connections. A regulator with gauge controlling a 0-60 psi air supply with associated fittings and a second instrument air gauge with associated fittings, is also mounted on this panel

- Master instrument air supply regulator

- 24 VDC Power supply

- Five, process quick-disconnect hose fittings allowing for connection to other process trainers, and pump down

- Quick-disconnect fittings located throughout, allowing for attachment of instruments

- Variable-area flow meter

- Two orifice plates and associated flanges, with tubing connections

- Industrial-quality, pneumatic control valve

- Pipe stanchion, allowing for attachment of differential pressure transmitters and pressure transmitters at varying heights

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- 33.5-in. L x 48-in. W x 76-in. H (860 x 1220 x 1930 mm)

- 375lbs. (170kg)

115V/60Hz/1Ph power

- Centrifugal Pump

- 20 Gallon Reservoir

- 3 Gallon Tank

- Circuit Breaker

- Power Distribution Panel

- Control Panel

- Instrument Air Supply Regulator

- 24 VDC Power Supply

- Variable Area Flow Meter

- Pneumatic Control Valve

- Two Orifice Plates

- Caster Set

- Pipe Stanchion

- #601-500 Use/Exercise Guide

- #600-006A - Economy Standard Test and Calibration Equipment Package

- #600-105 - Differential Pressure Gauge, 0-400” H2O

- #601-001EH Standard Instrument & Control Package (3-Variable) - Endress & Hauser