ANSI process pumps conform to the dimensional standards of the American National Standards Institute (ANSI). Specifically, these horizontal, end suction, single stage centrifugal pumps must meet the American Society of Mechanical Engineers (ASME) B73.1 standard.

This standard ensures that these centrifugal pumps are comparable in size and identical in interface and envelope dimensions, regardless of manufacturer. This allows these pumps to be interchangeable in size of suction, location of suction, discharge nozzles, baseplates, input shafts, foundation bolt holes, and mounting dimensions.

ANSI pumps are known for their compact structure, low vibration, and constant flow rate, making them ideal for a wide variety of applications. Mostly used in the chemical industry, ANSI pumps are also used in various process applications, as well as food processing, paper mills, pulp mills, refineries, ethanol production, and textiles.

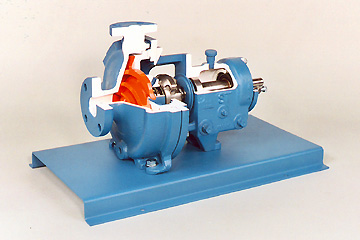

DAC Worldwide’s Goulds ANSI Centrifugal Pump Cutaway (278-105C) is an actual industrial Goulds-type pump that has been restored, sectioned, and mounted on a modular steel baseplate for classroom or lab training related to process pumps. The dissectible can also be mounted on a compatible DAC Worldwide workstation.

Industry-Standard Components Provide Realistic, Hands-On Training

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Goulds ANSI Centrifugal Pump Cutaway consists of an actual industrial-quality pump to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The Goulds ANSI Centrifugal Pump Cutaway is an actual sectioned industrial overhung centrifugal pump that has been restored using replacement hardware where necessary, retaining all key features. The pump features carefully-planned sectioning to allow its internal configuration to be exposed and showcased. The Goulds ANSI Centrifugal Pump Cutaway can be easily mounted and displayed on an electromechanical workstation (902F).