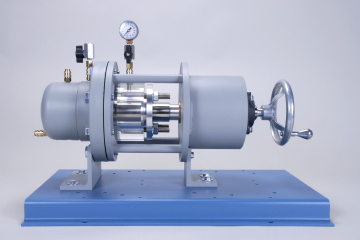

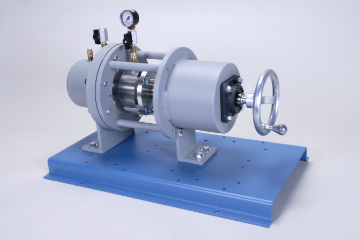

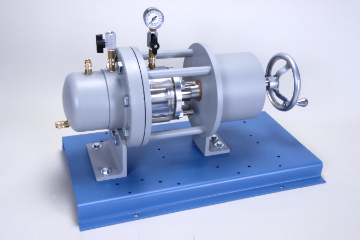

- 7-gauge formed-steel baseplate with provision for bench-top mounting, and mounting related workstation products

- Clear acrylic backhead and stuffing box allowing for complete visibility of the seal area, and for installation of many commercially-available mechanical seals.

- PVC simulated impeller housing with water inlet, vent, and drain

- Aluminum shaft assembly, incorporating a stainless steel 1-3/4" shaft sleeve

- Aluminum spacer assembly, connecting impeller housing and power-end

- Aluminum simulated power-end, incorporating sleeve bearing and radial ball bearing for representative pump shaft support and rotation

- Provision for attaching leak-off tubing or coolant re-circulation tubing in the seal area

- Quick-disconnect tube fittings at all fill, vent, and drain locations

- Aluminum lantern ring

- Aluminum packing gland

- Acrylic replacement packing gland for mechanical seal applications

- Handwheel, allowing for shaft rotation

- Provision for mounting on DAC bench, workstation and display products

- Packaging for shipment via motor freight

- Product Dimensions

(W x L x H)

13-1/2" x 24" x 14" (343 x 609 x 355 mm)

57 lbs (26 kg) - Shipping Dimensions

(W x L x H)

37" x 32" x 28" (940 x 813 x 355 mm)

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

- #280-001 - Compression Packing Assortment

- #280-004 - Type 1 Mechanical "Non-Pusher" Seal w/Elastomer Bellows

- #280-005 - Type 8 Mechanical "Pusher" Seal

- Spool of 3/8" braided packing

- Food coloring

- One (1) pressure gauge with quick-connect fittings

- Hose and air adapter assemblies

- Vent and fill valve assemblies

- Two (2) additional impeller housing gaskets

- Tool kit, including:

- 6" Depth scale

- Two (2) packing pullers

- Two (2) lantern ring pullers

- Packing pusher/driver

- 1-3/4" diameter packing cutting mandrel

- Six (6) pairs of disposable gloves

- Inspection mirror

- Crocus cloth

- Plastic tool box

- Connection to municipal water service required