- Valve Actuator Selection

- Actuator Design from Manual Hand-Wheels to Electrical Manipulators and Hydraulic Manipulators

- Construction and Operation of Manual Valve Actuators, Electric Valve Actuators, Hydraulic Valve Actuators, Pneumatic Valve Actuators, and Solenoid Valve Actuators

- Valve Position Indicator Types

- Advantages of Using Multi-Turn Actuators

- Operation of Multi-Turn Actuators

- How to Disassemble, Inspect, and Reassemble a Multi-Turn Actuator

- Techniques to Prevent Damage when Disassembling Valve Actuators

- How to Adjust a Valve Actuator Limit Switch

- Disassembly, cleaning and modification of actual industrial valve actuators.

- Cutaways allowing view of internal components in multiple areas.

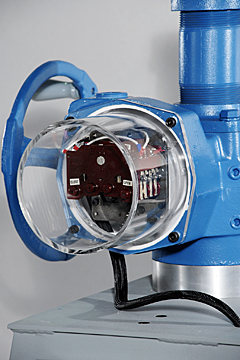

- Clear acrylic viewing windows for safety.

- Clear acrylic switch housing.

- Welded, heavy-duty mounting stand constructed from 1-1/2", 14 Gauge, steel tubing and 1/4", steel plate.

- Heavy-duty, anti-vibration, leveling feet.

- Simulated valve seat, with protective clear acrylic guards.

- 220 VAC, 3-phase motor controls (optional single-phase controls offered).

- NEMA control box and control panel with bi-directional switch, three-pole breaker and running lights.

- 28"W x 32"L x 45"H (711 x 813 x 1143 mm)

- 225 lbs (102 kg)

DISCLAIMER: Product Dimensions are approximate. Shipping Dimensions and Weights are for directional use only and may change based on manufacturer variables. For the most accurate Shipping Dimensions and Weights, please contact the manufacturer.

Includes NEMA Control Box and Control Panel, Simulated Valve Seat, Cutaways, 3-Phase Motor Controls, Manufacturer Manuals.